Hydraulic fittings and, in particular,

hydraulic reducers find space in numerous applications in the industrial world. Among these, we can mention:

- machine tools: they are equipped with numerous water and oil circuits which are necessary for the machine to effectively carry out its activity;

- molding systems: whether we are talking about presses, molds or automated cells there is the need to have circuits that convey fluids necessary for lubrication, thermoregulation or movement.

- ovens and heating systems: they have circuits with fittings and hydraulic reducers with fluids at very high temperatures.

Although these represent only a niche of industrial production, it seems quite clear that hydraulic fittings constitute a key point within these processes. In fact, an incorrect choice or the use of damaged components can lead to leaks and spills with serious consequences for those nearby.

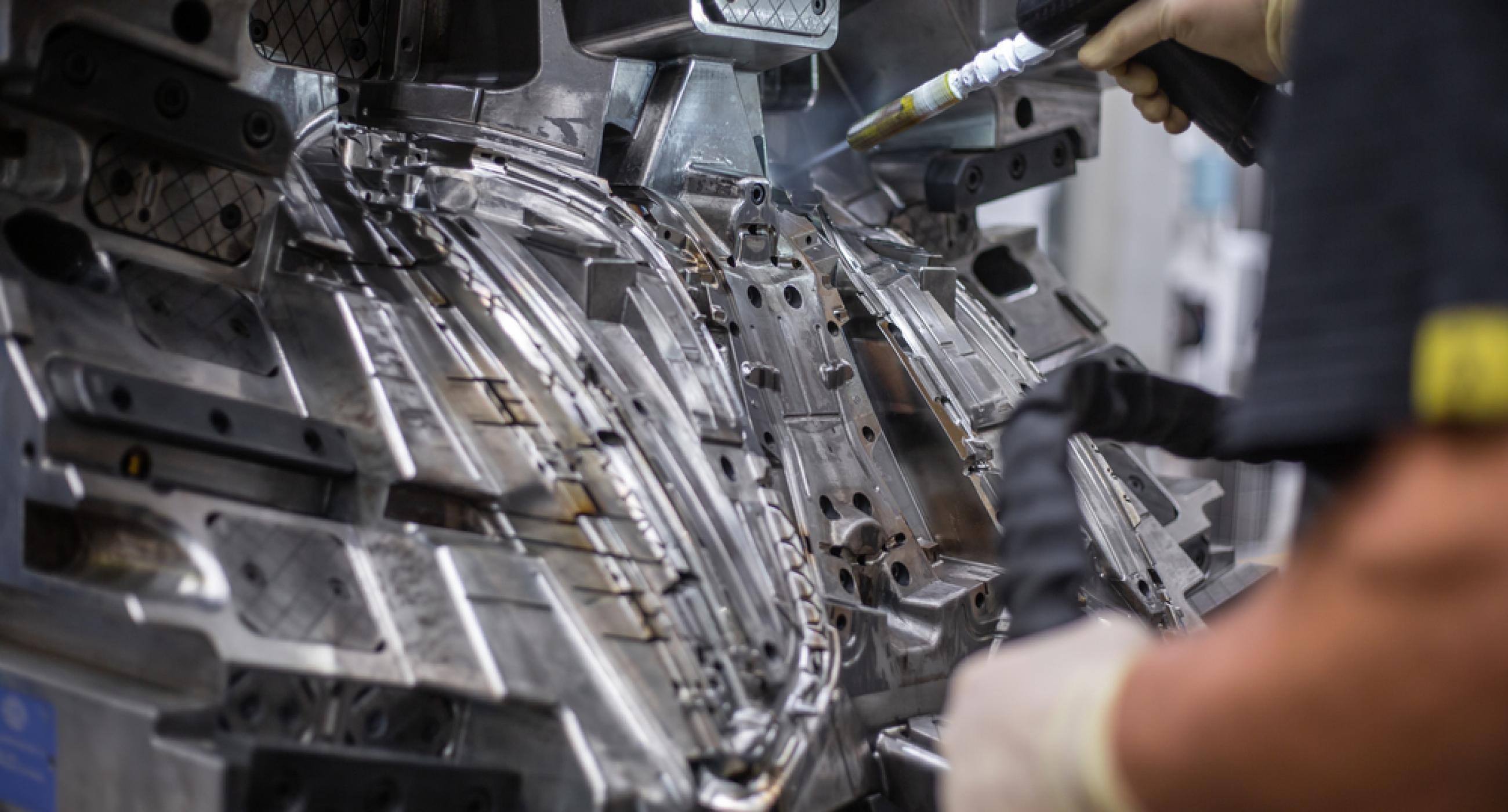

The circuits in the molds

The world of molds for die casting or injection molding constitutes a significantly important sector within the Italian and global industry. The role of a mold is to reproduce the shape for which it was designed: to do this it requires a series of circuits that perform different but equally important roles.

1. thermoregulation circuits: the thermal control of a mold is one of the most important factors for the creation of a product that respects the dimensional and technical characteristics for which the mold itself was designed. The conveyed fluid can be of various types and is usually found at temperatures that are not equal to the ambient temperature. From this it emerges that hydraulic reducers must have good resistance characteristics even at high temperatures to be suitable for the application;

2. hydraulic movement circuits: for the creation of undercuts and areas not opening with respect to the mold, hydraulic movements may be necessary. To do this, various types of cylinders are used which have oil circuits inside them which allow the movement and success of the molding phase;

3. lubrication circuits: to allow the control of temperatures, the extraction of the piece from the mold and the surface quality, lubrication circuits can be thought of which implement, as the name suggests, lubrication from the surface of the mould.

As briefly seen, analyzing the uses of the circuits in the mold, there are various functions that require the application of hydraulic reducers. In fact, the difference between the dimensions of the circuit in the mold and the dimensions of the line circuits may require the use of such reducers, with consequent variations in the speeds and pressures of the fluids.

Intertubi produces stainless steel and carbon steel fittings for any type of system, we are available for information and personalized quotes.